Vaccines are among the most powerful inventions in history, making once-feared diseases preventable.

WHO Director-General

Dr Tedros Adhanom Ghebreyesus

Source : WHO, 2024

Vaccine design has evolved over the past three centuries, driven by scientific innovation and technological progress, leading to more efficient products and production platforms.

Breakthroughs in glycoscience and immunology have established glycan-based conjugate vaccines as a key technology. These vaccines have a strong safety track record and are highly effective in preventing and protecting against bacterial infections.

Glycovax is redefining capsular polysaccharide conjugate vaccine design to create the next generation of carbohydrate-based vaccines.

Our technology platform utilizes fully synthetic carbohydrate antigens, providing key advantages over natural antigens, including optimal molecular consistency, precise control over conjugation and presentation, reliable production, the potential for enhanced safety, and broad efficacy.

It combines a customizable linker, the CRM197 carrier protein, and a novel immunostimulating adjuvant to develop cutting-edge vaccines.

With unprecedented flexibility, this platform enables the design of vaccines with optimal reactivity and efficacy, addressing unmet medical needs in infectious diseases and oncology.

Our Technology

GlycoForge

A novel, innovative platform technology designed to accelerate the development of new glycoconjugate vaccines.

Pipeline

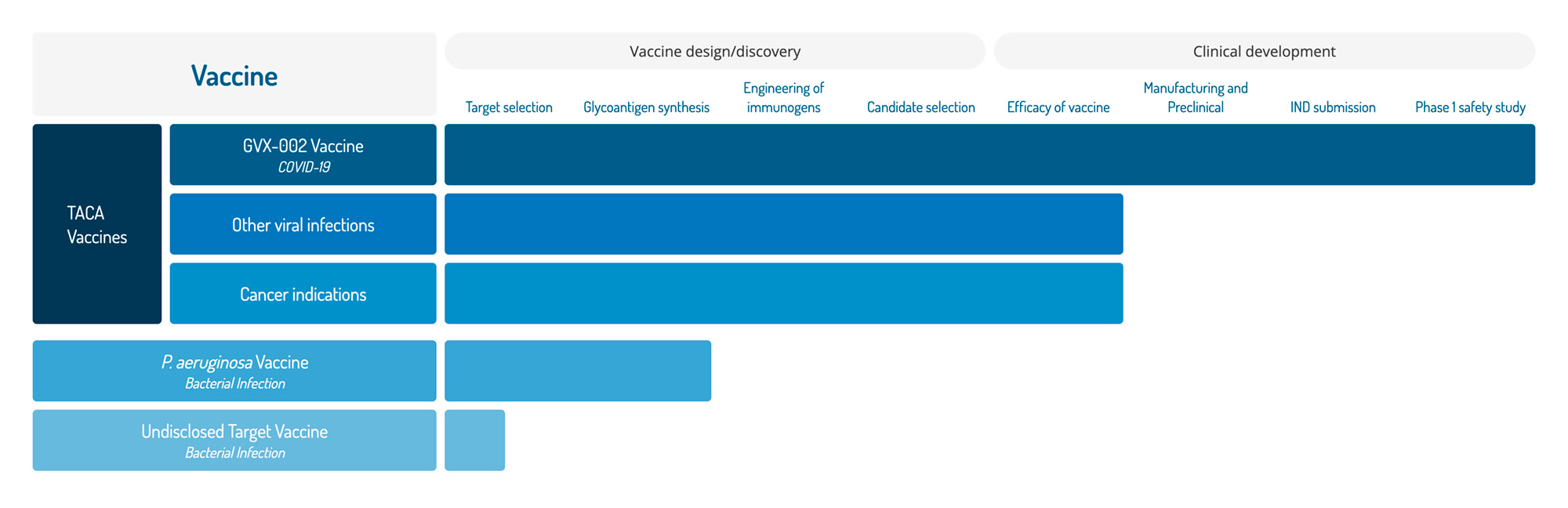

Vaccine

Vaccine design/discovery

TACA

Vaccines

Clinical development

Target selection

Glycoantigen synthesis

Engineering of immunogens

Candidate selection

Efficacy of vaccine

Manufacturing and Preclinical

IND submission

Phase 1 safety study

GVX-002 Vaccine

COVID-19

Other viral infections

Cancer indications

P. aeruginosa Vaccine

Bacterial Infection

Undisclosed Target Vaccine

Bacterial Infection

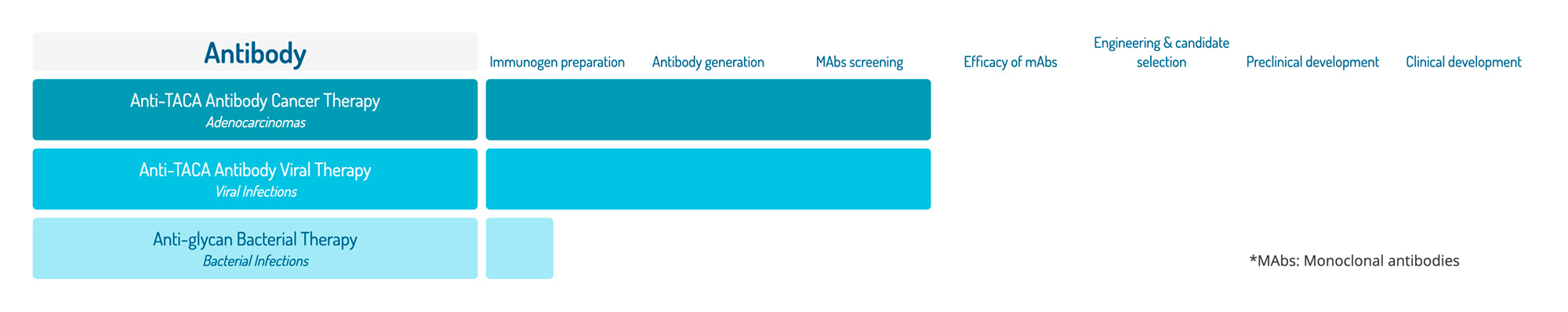

Antibody

Immunogen preparation

Antibody generation

MAbs screening

Efficacy of mAbs

Engineering & candidate selection

Preclinical development

Clinical development

Anti-TACA Antibody Cancer Therapy

Adenocarcinomas

Anti-TACA Antibody Viral Therapy

Viral Infections

Anti-glycan Bacterial Therapy

Bacterial Infections

*MAbs: Monoclonal antibodies

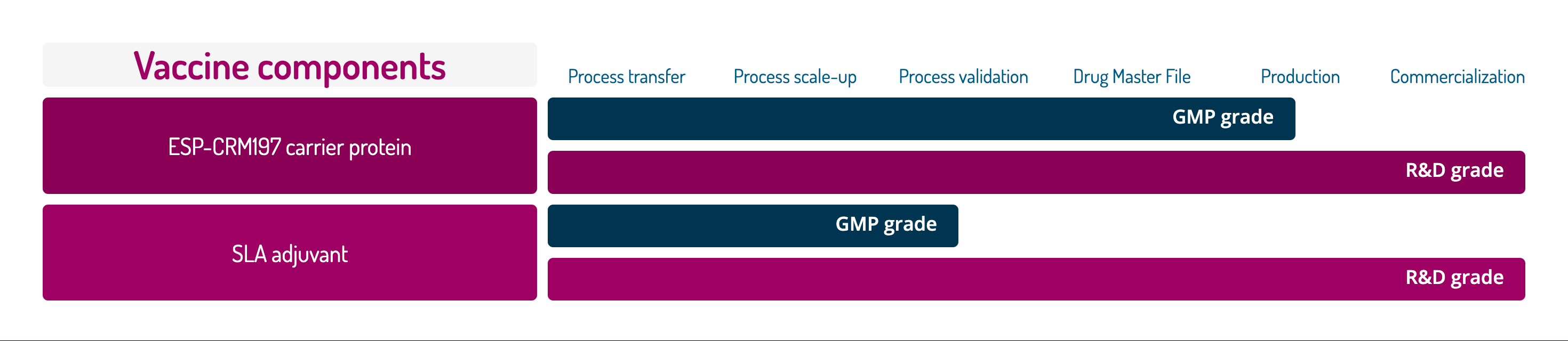

Vaccine components

Process transfer

Process scale-up

Process validation

Drug Master File

Production

Commercialization

ESP-CRM197 carrier protein

GMP grade

R&D grade

SLA adjuvant

GMP grade

R&D grade

Vaccine components

Two vaccine components are produced and commercialized by Glycovax Pharma for vaccine developers.

ESP-CRM197 Carrier Protein

High-Quality, Scalable, Compliant CRM197

ESP-CRM197 is produced to the highest quality standards and offered in multiple grades to meet the needs of vaccine developers at various stages of conjugate development.

It is backed by a Drug Master File (DMF) filed with the US FDA, simplifying the developers’ regulatory submissions.

ESP-CRM197 is produced by Espoir Therapeutics Inc., Glycovax branch dedicated to commercial manufacturing.

SLA Adjuvant

A potent, high-purity adjuvant compatible with various antigens

SLA (sulfated lactosyl archaeol) is a novel adjuvant obtained through a fully synthetic process. Its key advantages include:

- Wide applicability for different vaccine types and routes of administration

- Stimulating a balanced immune response (humoral and cellular)

- Enhancing antibody production

- Reducing the required antigen dose, thereby lowering costs

Soon to be produced under rigorous GMP standards to ensure high purity, SLA is designed for both human and animal immunization, thanks to its potent adjuvant activity.